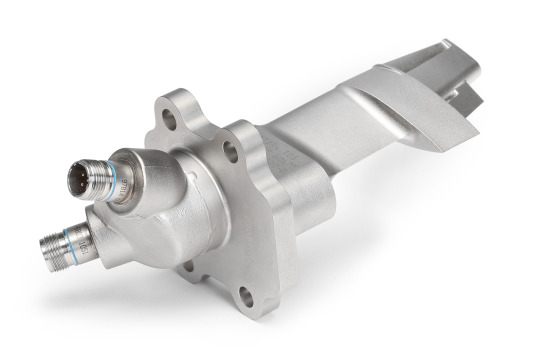

- It would normally take GE several years to design and prototype this part, but the GE team was able to shave as much as a year from the process. “The 3D printer allowed us to rapidly prototype the part, find the best design and move it quickly to production,” says Bill Millhaem, general manager for the GE90 and GE9X engine programs at GE Aviation. “We got the final design last October, started production, got it FAA certified in February, and will enter service next week. We could never do this using the traditional casting process, which is how the housing is typically made.”

posted 3285 days ago